Rapid prototyping can change the game for your small business.

Rapid prototyping has revolutionized the product development process in the past few decades. Ever-advancing technology has played a major role in its integration, and businesses in almost all sectors are embracing the possibilities of rapid prototypes.

Having the ability to quickly create a scale model or working version of a product allows businesses to efficiently develop and market a new product. It also expands the scope of manufacturing, allowing for faster exploration and realization of concepts, all while streamlining resources.

What is rapid prototyping?

Rapid prototyping has been around since the 1980s and is essentially the process of creating a scale model of your product through computer-aided technology. Using this technology, prototypes are fabricated in a short time period, hence the name.

Today, the process is significantly faster and more accessible than even 40 years ago, as the technology is more affordable and widely available. Even small businesses can afford 3D printing or other machinery used to mold, cast, mill, or turn to create prototypes

In contrast, traditional prototyping methods rely on mock-ups made from steel, wood, wire, clay or whatever other medium and materials serve the purpose. This process is time-consuming and tedious, and often, the end result isn’t always a true reflection of the product.

The 3 types of rapid prototyping

There are three types of rapid prototyping: additive, subtractive, and compressive.

The most common today is the additive method of 3D printing. In this process, solid 3D objects are created using successive layers of material. A digital file tells the 3D printer how to add each layer until the object is complete.

Subtractive methods include grinding, milling, or turning a block into a model.

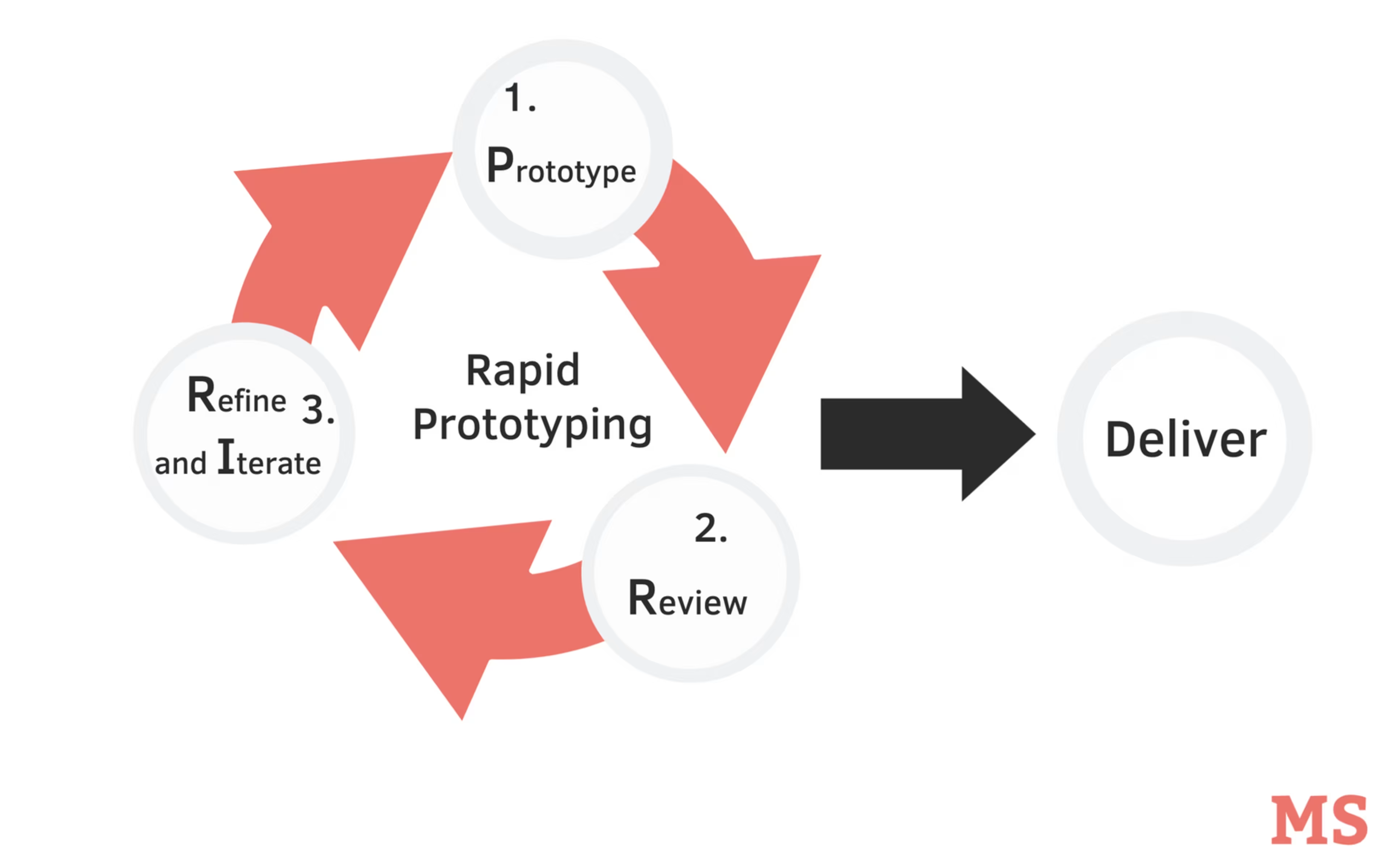

The compressive methods are molding, casting, or sinteringRegardless of which type of rapid prototyping is used, the process follows much the same steps: A prototype is created, it’s reviewed by project stakeholders, the design is refined, and a new iteration is created. The process timeline depends on the stakeholders and the refinements required, but the entire process could take as little as a day.

This diagram explains the process flow of rapid prototyping:

Steps involved in the rapid prototyping process (Source)

5 ways rapid prototyping can help your business

With an estimated 95% of new products failing within the first year of release, rapid prototyping provides a competitive advantage that reduces costs and drives profits.

Let’s take a closer look at how your business can benefit.

1. Cut down on product development lead times and costs

With rapid prototyping, you can significantly reduce the amount of time it takes to go from concept to production with a new product. And since you're reducing development lead time, you also cut down on development costs.

This also means you can make several prototypes throughout the design process. In doing so, you can see what is working and what isn’t, and adapt accordingly. It can be more effective for you and your designers to have a tangible model rather than working solely off a digitized plan or design.

The real feel a prototype brings allows you to iron out issues quickly and efficiently, and drastically reduces the time it takes to create a final product. The faster you go to market, the better your chances of finding a niche before your competitors.

Lower overall costs also mean you can be more competitive with your product's price point once the final version is ready for release.

2. Enhance customization

The ability to customize a product for a specific client or customer base greatly expands sales potential. Whether a client requires customization to tie in with their own unique offerings or there’s consumer demand for a secondary similar product with a few tweaks, customization can greatly increase bottom lines.

With rapid prototyping, if your product has yet to go to market, your designers and manufacturers don’t need to dedicate separate time to the customized model while they’re still working on regular production. These processes can occur at the same time.

When customization requests arrive after the product has gone to market, the development process usually cuts into production of the existing product. With rapid prototyping, however, you can easily create models that show the changes without impacting output of the regular product.

3. Create cost-efficient models

When bringing a new product to market, it’s important to have prototypes to show investors, employees, and future customers long before your product hits the market.

If you can turn out scale models in a cost-efficient manner, you don’t need to worry about only having one prototype. You can create several and share them with relevant stakeholders.

You can also create different versions of your prototype, showcasing your ability to customize or personalize the product. This can generate further excitement among investors and future customers, and exhibit your product and business' potential.

4. Capitalize on customer feedback

Consumer feedback is a critical part of any new product launch. If consumers aren't interested or impressed, your product and business won't succeed. You need to have an open line of communication with your target market to ensure you understand their thoughts and feelings about the product, and iterate accordingly.

This is another area where rapid prototypes can greatly benefit your business. You can run focus groups and feedback sessions using your prototypes, and update them quickly and cheaply using focus group feedback and then bring the changed product back to the group(s).

This back and forth shows your target market that you truly value their input while also validating your concept, giving you an idea of how your product will perform in the market.

5. Attain better market visibility

Essentially, the faster you can get a product from concept to market, the better your market visibility will be. And the more products you do this with, the better for your business reputation. You’ll enjoy greater market penetration at a faster rate, and your brand will grow at a quicker pace.

Brands generally don’t become household names with small product runs, nor do they attain effective market penetration. Rapid prototyping facilitates product quality even in larger runs, as the development process allows for refinement in production rather than after the fact.

Rapid prototyping provides the tools you need to get your product to market in a way that sets you up for success.

Rapid prototyping makes sense

Rapid prototyping is now a viable option for small businesses in all sectors. Due to advancing technology and lowering costs, your business can create mock-ups or entire scale models of a new product quickly and efficiently.

Now that you know the benefits, it’s up to you to decide how to integrate this process, from budget and operations to what technology you need to create your own rapid prototypes.

Whatever those answers, don't be the business that misses out on the opportunities and benefits that rapid prototyping provides.

Are you interested in becoming a guest writer for Capterra? Reach out to guestcontributors@gartner.com for details.