92% of SMBs say it’s important to shorten supply chains for long-term success.

Small and midsize businesses (SMBs) are embracing nearshoring[1] as a strategy to shorten their supply chains and achieve long-term success. Seventy-four percent of surveyed supply chain professionals at SMBs say their plan is to have most or all of their suppliers be in North America. Only 4% say they’ve no plans to nearshore.

While this trend is gaining momentum, many types of manufacturing aren't able to quickly build or create factories even if you’re ready to switch to them now. Therefore, the switch is happening gradually. In mid-2023, SMBs have nearshored an average of four suppliers in the past two years, and they know switching suppliers is not a quick or easy process. It requires careful consideration, a thoughtful vetting process, and effective integration of new suppliers into your supply chain management (SCM) system. This is where we can help.

We conducted the Supplier Relationships Survey* asking 300 supply chain professionals at SMBs about their experience and plans with their suppliers. We'll include insights on the nearshoring trend, tips for evaluating new suppliers, and recommendations for how to shorten your supply chain to help improve fulfillment times and build resilience.

/ Key highlights

SMBs are ready to switch faster than manufacturing can keep up: But the move is slow due to vendor availability. SMBs have switched an average of 4 vendors to ones in North America in the past 2 years.

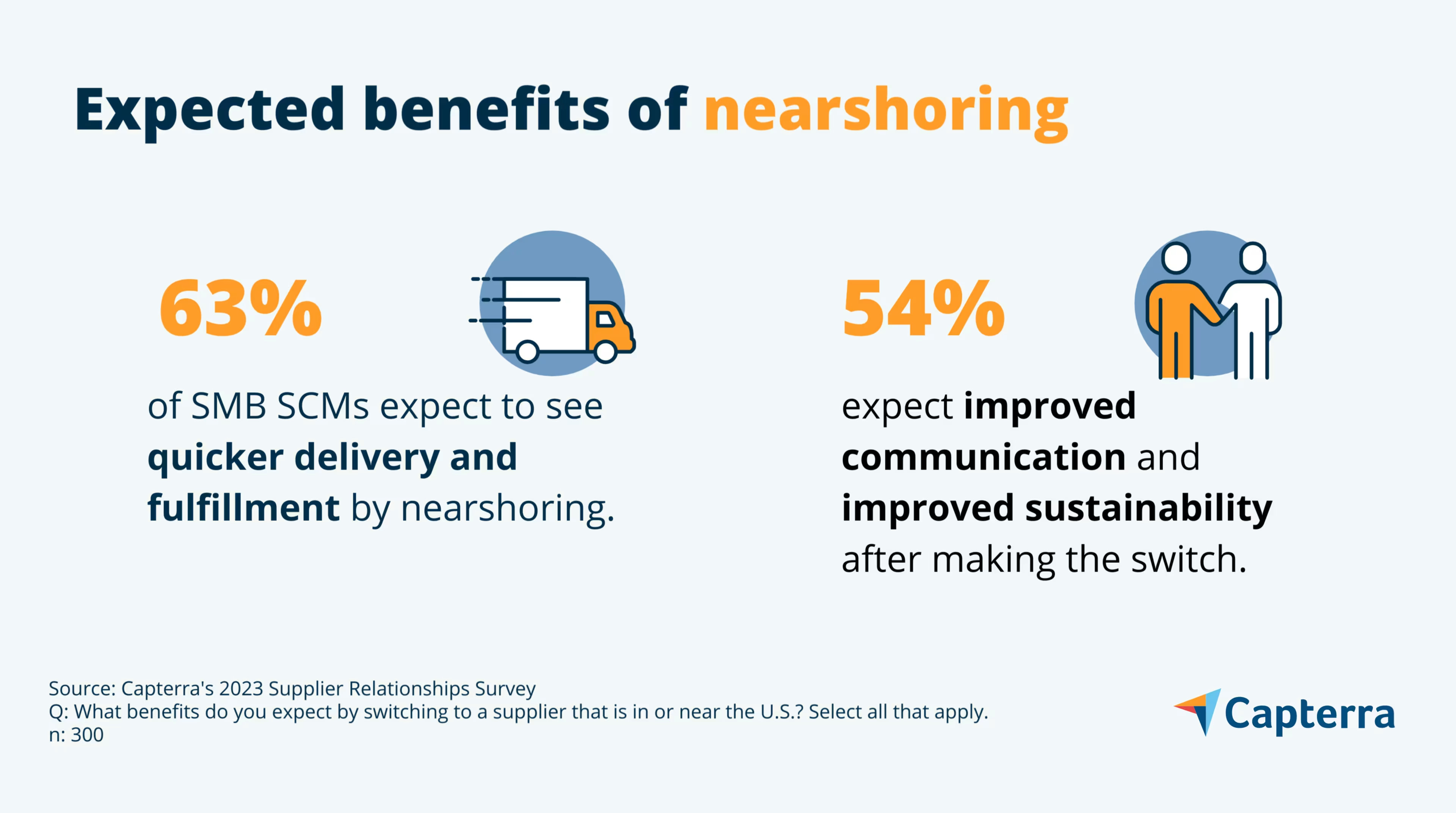

Expected benefits from nearshoring: Quicker delivery and fulfillment, improved communication, and improved sustainability.

Managing suppliers is high risk and complex: SMBs have an average of 27 key supplier relationships to maintain and typically are left to their own devices when comparing and shopping vendors.

Top industries making the switch: Computer and/or consumer electronics, food and/or beverage, and auto and/or other transportation. Clothing, furniture, and cosmetics lag. This aligns with current manufacturing plant trends.

Additionally, we've also included a bonus section below to answer a frequently asked question about how SCM professionals perform price comparisons between vendors.

Nearshoring helps with top two supply chain challenges

Shortening your supply chain gives you the opportunity to find new suppliers that can be a better fit for your needs and help reduce existing challenges. The top challenge SMBs face with their current suppliers is that they provide unreliable delivery timeframes. The majority of SMBs are expecting this to improve with nearshoring as 63% expect quicker delivery and fulfillment due to the closer proximity.

By sourcing closer to your customers, you reduce transit times and enhance responsiveness to customer demands, thereby increasing agility and resilience. Proximity also allows more face-to-face interactions, which fosters better collaboration and reduces the risk of miscommunication. Clear and efficient communication is essential for aligning production schedules and resolving issues promptly.

Addressing issues quickly helps with the second most common challenge SMBs report with their current suppliers: an inconsistent quality of delivered goods. In fact, product quality is the top priority for SMBs when selecting new suppliers, followed by pricing and sustainability. So when you're looking for new suppliers, don’t just settle for one that's closer in proximity to your operations. Make sure you're also taking the opportunity to find partners with more consistent product quality and sustainable business practices.

3 tips for switching to new suppliers

A majority of SMBs say they're effective in managing supplier relationships, including strengthening existing relationships (85%) and negotiating contracts and pricing (83%). But they feel the least confident in their ability to switch vendors to make strategic improvements.

When considering nearshoring, SMBs need to carefully evaluate and select suppliers that align with their needs. Here are three tips to help guide you:

Assess vendor capabilities: Before making the switch, thoroughly evaluate the capabilities of potential vendors. Along with pricing, consider factors such as their experience, expertise, production capacity, and quality standards. This evaluation will help ensure that the new supplier can meet your business needs.

Establish clear communication channels: Effective communication is crucial when switching vendors and both parties need to agree on the best ways to communicate. Regular meetings, frequent software system updates, and transparent communication will foster a strong working relationship and help address any issues promptly.

Plan for a transition period: Switching vendors may involve a transition period where both the SMB and the new vendor need to set realistic expectations regarding timelines, production ramp-up, and potential challenges. Openly communicate with the new vendor about your expectations and work together to minimize disruptions.

Once the switch is made, you should also closely monitor the performance of the new vendor. Establish key performance indicators (KPIs) to evaluate their performance against agreed-upon benchmarks. Provide timely feedback to the vendor, addressing any areas that require improvement or adjustment.

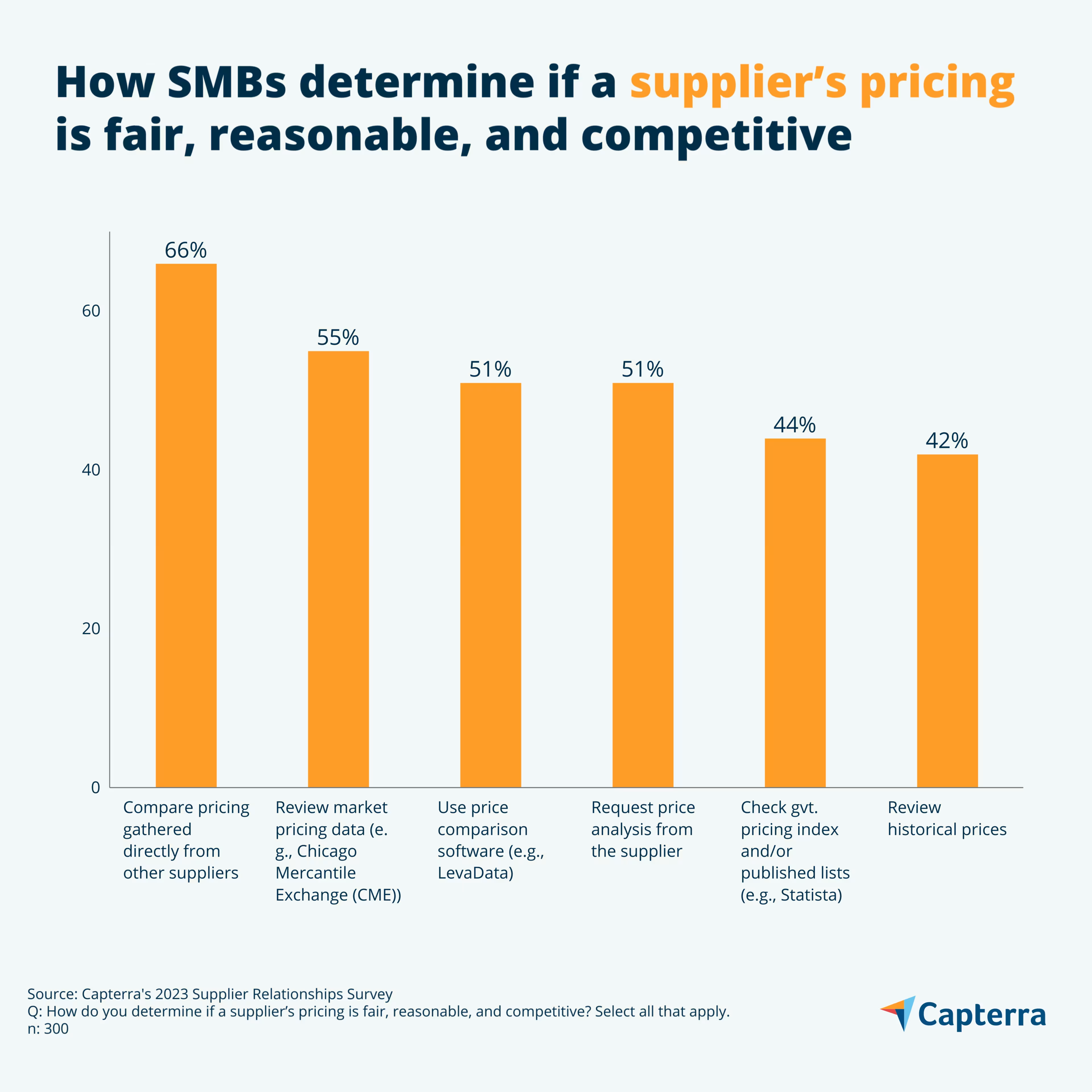

Bonus section: How SMBs are performing price comparisons

If you're responsible for negotiating supplier pricing, odds are you're unsure of how other SMBs are gathering benchmark data and might be wondering if you're doing the best thing or comparing the right information. This is a common question we get asked, and it even came up during our webinar, The 2023 Supply Chain Crystal Ball: Challenges and Solutions, with Supply Chain Brief. (You can request a copy of the webinar below.[1])

Here’s the breakdown of the research findings:

With 42% of our surveyed SMB SCMs reporting price volatility being a top challenge, we also asked how they negotiate price increases. Over half of surveyed SMBs use one or more of the following techniques when negotiating a price increase from a current supplier:

Take a collaborative approach, working with the supplier to come to a mutually beneficial agreement.

Negotiate on other aspects of the contract to offset the price increase, such as delivery times or materials used.

Present pricing data from other suppliers to use as leverage.

Request price matching based on our market research.

If you’re interested in software to help you manage prices, check out top software vendors and read user reviews for price optimization software here. Use the filtering options along the left to only see tools with features such as market data analysis and competitor price tracking.

Shorten to strengthen, but prepare for a gradual switch

Ultimately, successful nearshoring relies on the strategic selection of suppliers to not only shorten your supply chain, but also strengthen it. But the timing of when you're able to switch suppliers will vary greatly depending on your industry. Industries such as electronics, food and beverage, and automotive are seeing manufacturing move to the Americas much quicker than other sectors, such as clothing, furniture, and cosmetics.

As the nearshoring trend continues to evolve, SCM professionals must stay vigilant, adapt to changing global trade and macroeconomic dynamics, and leverage supply chain management software tools to stay ahead of the competition. Hopefully this report will help guide you toward a resilient and successful supply chain strategy.