Raw material shortages are a top concern, but not all companies are managing the risks effectively.

The supply chain is especially vulnerable to the increased rate and severity of weather disasters. Flooding and drought can cause critical transportation waterways and highways to be unnavigable. Overconsumption of water threatens its availability for future manufacturing efforts. And other materials, such as plastics and wood, are becoming increasingly more difficult and expensive to procure.

Capterra’s 2023 Manufacturers' Resource Management Survey* finds the majority of small to midsize business (SMB) manufacturers in the U.S. are concerned about the future availability of key raw materials and water, regardless of their industry.

But the study also finds that this majority is highly engaged in sustainability and risk management strategies to build resilience against these threats. And due to these focuses, SMB manufacturers expect to see many benefits from their sustainability strategies, the top ones being increased operational efficiencies, reduced costs, improved brand reputation, and investment in society’s well-being.

/ Key findings

80% of SMB manufacturers say they’re moderately to severely concerned about the availability of raw materials needed over the next year.

Plastics, oil, and plant-based shortages top the list.

71% report moderate to severe concerns about the long-term availability of water for their operations.

More than half are focusing on both sustainable packaging and shipping strategies to reduce environmental impact.

94% of SMB manufacturers say they’ve been successful in their progress toward achieving their sustainability goals.

Raw material shortages increase costs and impact operations

The majority of SMB manufacturers (80%) report moderate to severe concern about the availability of raw materials needed for their products over the next year. Raw material shortages can disrupt production schedules, increase costs, and even lead to lost sales.

The small business struggle

Smaller businesses often lack the financial reserves and bargaining power that larger corporations have, making them more vulnerable to price fluctuations and supply chain disruptions. Also, they often rely on a limited number of suppliers, which increases their exposure to risks associated with those suppliers' operations, such as natural disasters or geopolitical issues.

Concerns are high across most raw materials, but let’s take a look at the top three key areas.

Shortages in the raw materials your operations and/or product requires can impact your business expenses in the following ways:

Product and packaging: Plastics are a common material for packaging and many products. Shortages can lead to increased costs, affecting the overall product cost and potentially reducing profit margins.

Operational processes: Fluctuations in energy sources and machine lubricants can result in higher prices, impacting your manufacturing processes and increasing operational expenses.

Transportation: Shortages in fuel sources means increased prices, which can lead to increased shipping and transportation costs, affecting overall profitability.

Production delays: Shortages of plant-based materials can lead to increased costs, delayed projects, and lower production output. Industries such as construction and furniture that heavily depend on wood need to be especially aware of this growing concern.

In all cases, SMB manufacturers must carefully manage their supply chains, monitor commodity prices, and consider alternative materials or suppliers to mitigate the impact of future shortages. These challenges highlight the importance of risk management and resilience in manufacturing operations.

How to prepare: Implement risk management software

In addition to product design planning to reduce reliance on threatened raw materials, you can begin risk management strategies now. Rather than trying to fortify every link in the chain against any kind of risk, leverage a supply chain management system, risk management software, or other analytics tools to identify the most serious risks and where they would have the greatest impact in your business.

Look for solutions that offer simulation capabilities so you can run what-if scenarios and prepare for the highest-risk and highest-probability of occurring ones. These tools can help you prioritize risks and take proactive measures, such as boosting inventory at one location or adding secondary supply sources.

Water concerns also drive sustainability strategies forward

The majority of SMB manufacturers (71%) are moderately to severely concerned about the long-term availability of water for their operations. Food/beverage and apparel manufacturers comprise most of the severely concerned ones, whereas the less or not concerned are spread out across the more machinery, electrical equipment, and metals-based companies. This is in line with what we’ve seen happening with large enterprises as well.[1]

SMB manufacturers have set the same top three sustainability goals across all industries included in this study:

Update product and/or packaging

Use more efficient shipping practices

Improve employee working conditions

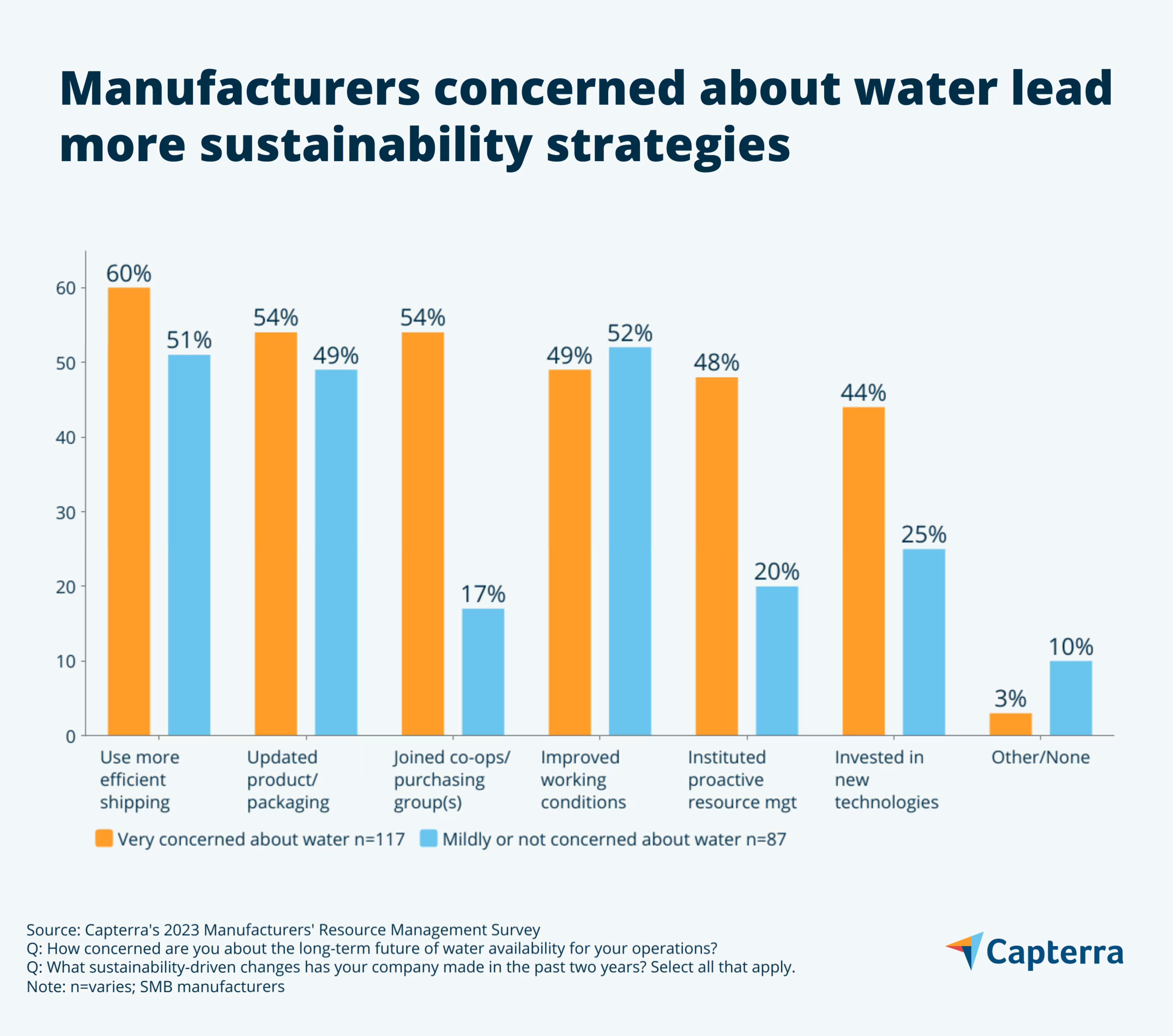

But participation in other goals for sustainability look very different when we compare the actions taken by companies based on their level of concern over water as a resource.

Manufacturers with high concerns over future water availability are about twice as likely to be setting additional sustainability goals compared to the businesses with mild to no concerns. These goals include:

Institute proactive resource management (e.g., water management for manufacturing machines).

Invest in new technologies, such as robotics or IoT devices.

Join eco-conscious collaborative(s) and/or purchasing group(s).

How to prepare: Level up your technology now

Check to see if your current supply chain management software has features for tracking sustainability goals and water resource management. If not, there’s a host of tools available that are specifically designed to help you manage your sustainability goals.

Emerging technologies are more readily available and should be considered as well. For example, machine learning models allow you to run what-if scenarios and review interpretations of the different outcomes. Doing this will provide important data points for strategic decision-making and goal setting.

To get the most out of these tools, businesses also need to increase the number and types of monitoring devices used throughout their operations. These devices can send data back to your SCM system, increasing the visibility and accuracy of your view of operations and resource usage.

Increase your sustainability with thoughtful packaging

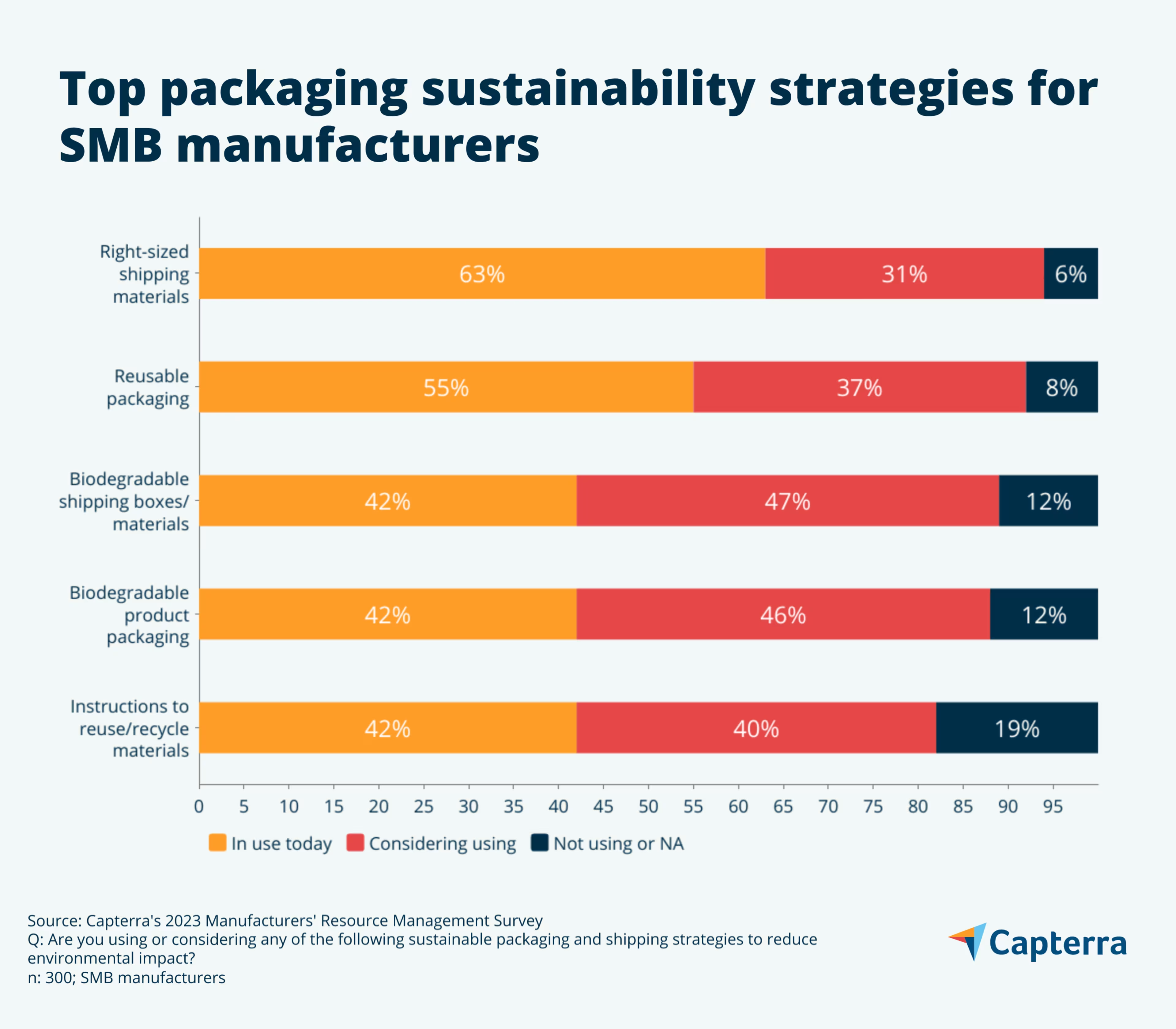

Over half of SMB manufacturers are currently working on sustainable packaging strategies to reduce environmental impact. In fact, only about one out of nine aren’t doing or considering packaging as a sustainability solution. Implementing sustainable packaging is a strategic move that benefits both businesses and customers.

From a business perspective, embracing sustainable packaging not only aligns with the growing environmental consciousness but also reduces costs in the long run and fortifies your business against any future materials shortages discussed earlier. For your customers, sustainable packaging demonstrates a commitment to environmental responsibility, which can foster brand loyalty and attract eco-conscious consumers.

Sustainable packaging is a win-win scenario where your business reduces environmental impact and enhances its competitiveness and customer satisfaction.

How to prepare: Focus on sustainable packaging strategies

Manufacturers can incorporate eco-friendliness into packaging operations and production through various approaches. Here are three impactful ways businesses can enhance sustainability through their packaging choices:

1. Use eco-friendly, recyclable packaging materials

Our study finds 55% of SMB manufacturers currently use recyclable/reusable product packaging, and another 37% are considering it. When selecting packaging materials, including boxes, containers, or mailers, pick ones that can be readily reused or safely recycled.

For example, switching to unbleached paperboard and shipping materials derived from plant fibers can help not only your customers properly recycle your product but it also allows your facility to do so too. You can also consider incorporating recycled plastic materials, such as bottles and single-use bags, into your mailers and containers, promoting a more circular supply chain.

2. Educate customers about how to reuse/recycle your goods

Only 42% of SMBs currently include instructions for customers on how to reuse/recycle material, yet another 40% are considering doing so. Educating your customers about recycling or reusing your product and/or the packaging can help support not only your sustainability efforts, but the whole community.

Here’s some ideas to get you started:

Incorporate a general label on your product(s), featuring a recycling icon and the terms “reusable” or “recyclable.”

Post step-by-step instructions on how to reuse and recycle your product(s) on your website and include a QR code to this page on the product and packaging.

Run social media campaigns to raise awareness and encourage participation in recycling efforts.

3. Explore biodegradable alternatives

Only 42% of SMB manufacturers are currently using biodegradable materials for both product packaging and shipping boxes/materials. Compostable packaging allows consumers to compost at home and commercially with local composting/recycling centers. These materials break down in compost, contributing to the reduction of waste and environmental impact.

For example, plant-based materials made from mushrooms, corn, and food waste offer sustainable packaging alternatives. In fact, bioplastics derived from mushrooms and/or cornstarch can make durable packaging solutions that protect food products during shipping without affecting flavor.

If you’re in charge of packaging at your company, or just want to learn more, check out this newsletter, Sustainable Packaging, for detailed information and ideas about how to improve your packaging.[2]

Agility and flexibility are crucial for increasing manufacturing resilience and sustainability

Manufacturers must be proactive and adaptive in managing their supply chains, preparing for future raw material shortages, and flexible to ever-evolving market dynamics. These strategies should be integrated into the core of manufacturing and supply chain operations, recognizing that sustainability is a strategic imperative for long-term success.

As businesses navigate the challenges of increasingly disruptive environmental realities, those that prioritize sustainability will find themselves better positioned to thrive, adapt, and prosper in the years ahead.

Recommended reading

Consumer Expectations for Sustainability Are Accelerating Despite Inflation

Eighty-four percent of consumers have purchased a sustainable product in the past six months. Learn more about consumers’ buying behavior around sustainable products so you can design an effective strategy to attract new customers.

Sustainability Software Buyers Guide

Learn about how sustainability software assists in tracking and analyzing operational data, such as energy consumption, waste production, and greenhouse gas emissions, to inform sustainability initiatives such as managing the carbon footprint of supply chain processes.

A Customer-Centric Supply Chain Strategy Evolves As 80% of SMBs Invest in Sustainability

Supply chain professionals should drive a “just-the-customer” approach, not “just in time” as customers are expecting more ethically- and sustainably-built products, even if they cost more. Read about how you can make the shift and increase sustainability efforts.